Many businesses have succumb to the high cost(s) associated with color printing and have accepted an attitude of, “that’s just the way it is, color printing supplies are expensive!” Although the latter of the statement is true, the fact is it doesn’t have to be that way. There are several ways businesses can gain more control of the money being spent monthly to manage their color printers. Many businesses today choose to purchase color printers because it allows them the ability to print color when needed. Let’s dig a little deeper into the operative words ending the previous sentence, “when needed.”

One of the biggest factors to high color printing costs is directly related to printing content unnecessarily in color. Most businesses find that their employees print pages directly from websites, which eat up a lot of toner and ink (most websites cover about 15% of a printed page on average, meaning your toner cartridges will empty THREE times faster). The reason for this is simple, because websites are content heavy with lots of graphics your users end up printing out a page that uses a lot of toner or ink to produce and that translates into dollars. Let’s look at strategy that will take the “un” out of your unnecessary color printing!

Now how can you gain control over your users unnecessary color printing? Well the first thing you should do when installing any color device into your operation is to make sure the print driver installed has been set to default print jobs to either monochrome or grayscale printing. This will allow the users to select color printing “when needed”, which will save your company lots of money in the long run. Also check your print drivers “quality” print settings. These allow you to select print density and can be set for both monochrome and color print jobs which will further reduce the amount of toner or ink needed to produce a printed page. Another quick cost saver, which rings true for both monochrome and color printers, is to utilize high yield cartridges where available.

The last strategy (aka “Right-Sizing”) requires you to review how many pages each color printer is printing monthly. Next you need to determine the actual CPP (costs per page) for each color device (divide the costs of the cartridge by the page yield=CPP). Since you are analyzing color devices remember to include all consumable kits, i.e. transfer kits, drum kits, waste kits and fuser kits. Once you have the CPP’s for each consumable you can now calculate the monochrome CPP (Black cartridge CPP + Kit consumables CPP’s) and the color CPP (Total of all consumable(s) CPP’s). Now that you have determined the CPP’s for your color devices go back and review how many pages your color printers are producing monthly. Place your lowest CPP printers in the areas or departments where the most pages are being printed monthly. Viola, you have successfully “right-sized” your print fleet!

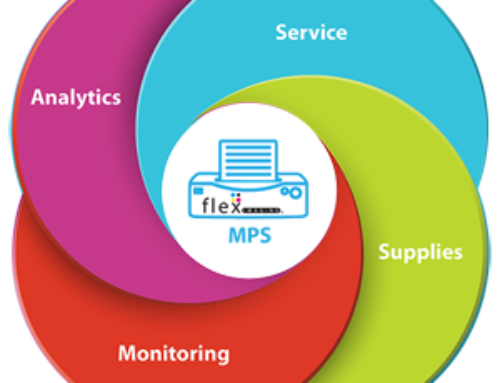

Hopefully these cost saving strategies will help get you on your way to reducing the color printing costs incurred by your organization! If you are still confused, are in the Atlanta metro area and would like Flex Imaging to come to your location to analyze your devices, feel free to give us a call at 770-591-5563.

Leave A Comment

You must be logged in to post a comment.